Duplex Stainless Steel Fasteners in the grade SAF 2205®(UNS S32205), UNS S31803 & UNS S32900 are often needed in the fight against corrosion when 316 grade just isn’t enough, such as being constantly submerged in salt-water . An important feature of Duplex stainless steel is that its pitting and crevice corrosion resistance is greatly superior to that of 304 or 316 grade Stainless Steel. This combined with high mechanical strength and ductility makes it an excellent material for so many applications.

The chemical composition based on high contents of chromium, nickel, and molybdenum improves intergranular and pitting corrosion resistance. Additions of nitrogen promote structural hardening by interstitial solid solution mechanism, which raises the yield strength and ultimate strength values without impairing toughness. Moreover, the dual-phase microstructure guarantees higher pitting resistance and resistance to stress corrosion cracking in comparison with conventional stainless steel.

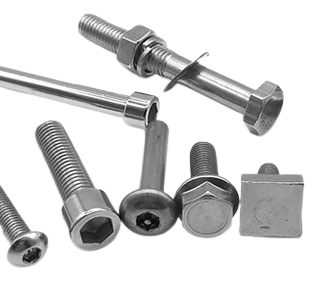

Duplex Steel Fasteners are available in various types such as screws, bolts, nuts, washers, anchor, rivet, studs, hex nuts, stud bolts, plain washers, heavy hex nuts, T bolts, eye bolts, coupling nuts, machine screws, jam nuts, lock washers, etc.

Duplex fasteners are ideally made with forged heads and rolled threads with the heating in the forging process carefully temperature controlled. Duplex fasteners can be CNC machined from round or hex bar. Threads should be rolled rather than machined to ensure smoother, stronger threads which in turn increases the thread’s yield strength, improves surface finish, hardness, and wear resistance.

When Hot Forging the fastener head, temperature control is critical. When heating Duplex you must avoid prolonged time in the critical temperature zone as this encourages unwanted Nitrides and Carbides to form. It is important that digital control equipment is used to quickly heat through this temperature zone and automatically remove from the heat source when the temperature is optimum for forging. Any Duplex item then undergoes laser marking to ensure traceability of the fastener through the supply chain. EN 10204 Type 3.1 test Certificates are also provided.

• Duplex Stainless Steel Grades: F51, F52 & F60

• Fastener Stadard Sizes: M6-M64; Nut: M3-M64

• Threaded Rod:4-2000mm (all thread, double end thread)

• Standards: DIN 931, DIN 933, DIN 934, DIN 439, DIN 835, DIN 7991, DIN 975, DIN 976, DIN 912, ISO, JIS, ANSI/ASME, BS, etc

• Surface Coatings: Mirror Buffed, Hot Dipped Galvanizing, Epoxy Coating, Electro Polished, Passivation, Teflon Coating, Oxidized, Zinc Plating, Chrome Plating etc

Zeon’s Duplex fasteners are a high quality option, made with excellent quality control and traceability. We have a range of Duplex & Super Duplex Fasteners to suit your needs. Can't find what you are looking for? Contact us to place an inquiry and see how we can help you.